Why I spent $1 million on a razor...

Why I spent $1 million on a razor... The key to a good startup business: solve a common problem... Two years in the making, OneBlade is ready to ship...

Editor's note: The stock market is closed today in celebration of Independence Day, so Porter is using the Friday Digest to talk about something completely different...

![]() Today I'd like to tell you why I spent more than $1 million developing a new razor for men's shaving. I want to share the secrets I've learned about what makes for a great shave... and how difficult it is to make a perfect leading razor edge. I spent nearly two years looking for and then trying to make the perfect blade. And I believe I've done it.

Today I'd like to tell you why I spent more than $1 million developing a new razor for men's shaving. I want to share the secrets I've learned about what makes for a great shave... and how difficult it is to make a perfect leading razor edge. I spent nearly two years looking for and then trying to make the perfect blade. And I believe I've done it.

Today's Digest is the story of my startup razor business, OneBlade. It's the story of how a small group of investors decided to take on some of the world's largest corporations by focusing on materials, innovative design, and the highest possible manufacturing quality. I hope the story inspires your own entrepreneurial ventures... and, of course, I hope you'll try our new razor.

![]() Let me start with the most obvious point. I decided to build a better razor – vastly better than what you can buy anywhere else right now – because for decades, I hated my razors. No matter what brand I bought, they were always made from cheap plastic. They all used ultra-cheap, mass-produced cartridge razors. To me, these blades seemed like little more than sharpened tinfoil. They became dull almost immediately. They tugged and pulled at my skin. They gave me ingrown hairs and razor burn. They clogged with hair if my beard was longer than a day or two of growth. And worst of all... they were very expensive.

Let me start with the most obvious point. I decided to build a better razor – vastly better than what you can buy anywhere else right now – because for decades, I hated my razors. No matter what brand I bought, they were always made from cheap plastic. They all used ultra-cheap, mass-produced cartridge razors. To me, these blades seemed like little more than sharpened tinfoil. They became dull almost immediately. They tugged and pulled at my skin. They gave me ingrown hairs and razor burn. They clogged with hair if my beard was longer than a day or two of growth. And worst of all... they were very expensive.

I'm almost certain you know what I mean. But you probably don't understand why cartridge-shaving systems are problematic. Mike Sandoval is a shaving expert who runs the website shaving101.com. He describes the core failure of all cartridge razor systems this way...

The cartridge razor system is appealing to many men because it is advertised to be modern and high performing... The problem is that the blades of a cartridge are close together with extremely small spacing between each cutting edge. The razor is unable to cleanly cut hair without requiring multiple passes along your skin, catching and pulling long stubble, as well as constantly clogging during the shave.

![]() Over the years, the situation has only gotten worse. Most cartridge razors have become more complex and more expensive. But – in my opinion – they haven't improved on their basic utility. They're not delivering a high-quality, non-irritating shave. In fact, I believe the more blades that are in a cartridge, the likelier it becomes that the user will suffer significant skin problems.

Over the years, the situation has only gotten worse. Most cartridge razors have become more complex and more expensive. But – in my opinion – they haven't improved on their basic utility. They're not delivering a high-quality, non-irritating shave. In fact, I believe the more blades that are in a cartridge, the likelier it becomes that the user will suffer significant skin problems.

In our privately funded research and design efforts (we used a leading industrial design firm in Brooklyn, New York), we found the most important variable in shaving was the space between the leading edge of the razor and the guard protecting it. Too much space meant that cutting yourself was inevitable. Too little space meant that it was nearly impossible to cut anything. The next time you look at a cartridge razor, notice how much more space is in front of the first blade in the cartridge compared with the spacing between each additional blade. Our testing showed the first blade is the one doing the actual cutting.

So... what are the other blades really for? I'll let the designers of the world's leading cartridge brand explain that...

In 1998, the designers of the world's leading multi-bladed cartridge razor told The New Yorker...

We knew that if you had more blades, you'd be able to cut more hair. But we found that what you gained in efficiency you lost in comfort, irritating the skin too much in exchange for the closeness.

So they knew skin irritation was going to be a problem. But did they stop trying to add blades or other forms of complexity? Nope. They kept on going. And they didn't stop by adding two or three blades. The marketing departments of the major cartridge makers realized people would pay up for more blades. So they kept adding more. The consumer didn't seem to care about the quality of the blades, only the number of blades. And so "razor wars" began – three blades, four blades, five blades, vibrating blades, blades on spinning balls, etc.

But all of these razors are plastic. And they all use some variety of cartridge razors with cheap steel blades.

I know from years of experience that none of these products will give me a decent shave. Instead, as I mentioned, they all give me razor burn and ingrown hairs. They all look and feel cheap. I wanted a "real" shave. I wanted a much better tool.

![]() I discovered the solution in Italy. I was on vacation with a group of friends. We were in Rimini on the coast of the Adriatic Sea. One of the people in our group suggested we visit an old-fashioned barbershop and get a straight-razor shave. I was nervous about letting someone put a sharp razor blade against my face, but I was curious, too. I had seen older men shaving this way and wondered if they knew something I didn't.

I discovered the solution in Italy. I was on vacation with a group of friends. We were in Rimini on the coast of the Adriatic Sea. One of the people in our group suggested we visit an old-fashioned barbershop and get a straight-razor shave. I was nervous about letting someone put a sharp razor blade against my face, but I was curious, too. I had seen older men shaving this way and wondered if they knew something I didn't.

![]() It was the blade I couldn't forget. It was unlike anything I had ever felt on my skin. There was no resistance at all. Instead of feeling this shave, I could really only hear it. Cool pressure, followed by hundreds of tiny clicks as my beard came off. It was like the sound of dominoes falling. It was effortless. My skin felt like new. Not only was there no hair of any kind, but my skin was reinvigorated and cleaner... so clean that it felt like it had never actually been clean before in my whole life. This wasn't shaving – at least not the kind of shaving I'd known before. This was a supreme luxury experience, a kind of indulgence.

It was the blade I couldn't forget. It was unlike anything I had ever felt on my skin. There was no resistance at all. Instead of feeling this shave, I could really only hear it. Cool pressure, followed by hundreds of tiny clicks as my beard came off. It was like the sound of dominoes falling. It was effortless. My skin felt like new. Not only was there no hair of any kind, but my skin was reinvigorated and cleaner... so clean that it felt like it had never actually been clean before in my whole life. This wasn't shaving – at least not the kind of shaving I'd known before. This was a supreme luxury experience, a kind of indulgence.

![]() And so that became my goal. I wanted to build a razor that could safely and conveniently deliver a straight-razor-quality shave to anyone at home.

And so that became my goal. I wanted to build a razor that could safely and conveniently deliver a straight-razor-quality shave to anyone at home.

Seems simple, right? Just go out and buy some high-quality steel and sharpen it. Presto. But it hasn't been simple. The secrets of what we've discovered are below, as well as a few pictures I think you'll find interesting. But before I get to the details, I want to thank the investors who joined me in this quest to build the perfect razor. I was surprised so many of my close friends were willing to invest a substantial amount of money in helping finance my dream.

I also want to thank Tod Barrett, our tireless CEO. Tod has traveled all around the world meeting with manufacturers and our design studio team in New York. Tod – who was formerly the CEO of legendary small-appliance developer Ronco – took a big chance when he accepted our job offer. He's the driving force in this business. Without his efforts, none of the things you'll read about below would have been possible. If you end up loving your OneBlade razor – and I know you will – give thanks to Tod. I do every time I shave.

![]() Our quest began almost two years ago. We raised around $2 million in seed capital from a list of friends and family. Our original business model focused on building our own blade. We knew that to deliver on our promise of the world's finest shave, we would need the highest-quality blade available anywhere.

Our quest began almost two years ago. We raised around $2 million in seed capital from a list of friends and family. Our original business model focused on building our own blade. We knew that to deliver on our promise of the world's finest shave, we would need the highest-quality blade available anywhere.

We knew manufacturing our own blades would be expensive. I believed people would pay for quality once they tried it. We experimented with new materials – like ceramics – trying to create a blade that was sharper, smoother, and longer-lasting than steel.

But we ran into what we now call the "leading edge" problem.

It turns out that sharpness is not the key to a world-class shave. Of course, the edge needs to be sharp... but more important, it needs to be flawless. The leading edge has to be so smooth that you can only see it with a microscope.

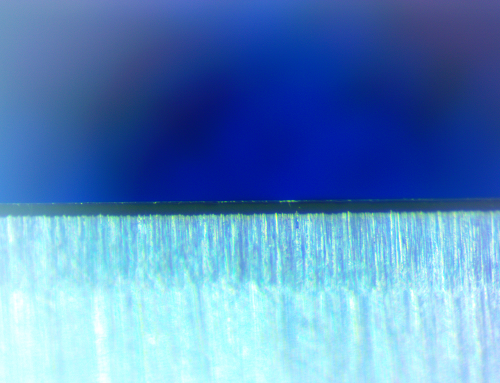

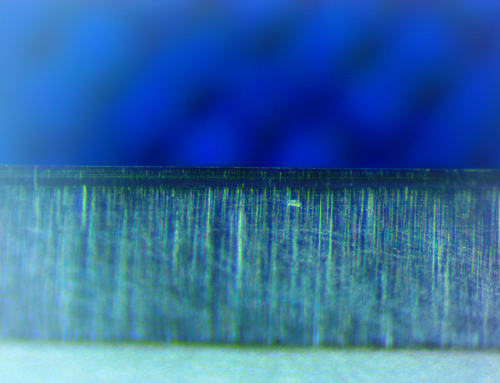

![]() Look at these two pictures from one of our manufacturing partners. These are actual images of the leading edges from two of the blades we used in our research and development program...

Look at these two pictures from one of our manufacturing partners. These are actual images of the leading edges from two of the blades we used in our research and development program...

Feather's blade

Competitor's blade

You'll notice that one of these blades has an edge with a perfectly uniform appearance... while the other has hundreds of "striations," or minor imperfections. These tiny imperfections – far too small to see with the naked eye – cause the blade to "burn" against the skin.

![]() In our research, we discovered the secret to a comfortable shave was a perfect leading edge. And few people around the world know the secret of how to make perfect leading edges in volume. Yes, you can strop a blade – polishing and sharpening it like folks using actual straight razors do. But it's not feasible to hand strop tens of thousands of blades each week. We quickly realized our plan to make our own proprietary blades wasn't feasible. It might take us 10 years to perfect our own in-house blades. So whose blades did we decide to use?

In our research, we discovered the secret to a comfortable shave was a perfect leading edge. And few people around the world know the secret of how to make perfect leading edges in volume. Yes, you can strop a blade – polishing and sharpening it like folks using actual straight razors do. But it's not feasible to hand strop tens of thousands of blades each week. We quickly realized our plan to make our own proprietary blades wasn't feasible. It might take us 10 years to perfect our own in-house blades. So whose blades did we decide to use?

Ask any barber or shaving expert anywhere. Everyone who knows shaving knows that Feather, a Japanese firm, makes the world's best blades. Feather supplies barbershops all over the world. My first straight-razor shave in Italy? The barber was using a Feather blade. These razors are made with super-high-quality Japanese steel. They have a proprietary finishing process that leaves their blades with a perfect leading edge – the best we found in our research. And best of all, Feather makes a single-edge blade just like the kind we were trying to make for our new razor. Problem solved.

![]() While we plan to continue to invest in new materials and our own blades, the simple fact is that none of the blades we built over the last two years were as good as Feather's. Our goal isn't necessarily to build blades. We just want to deliver the world's best shave, period.

While we plan to continue to invest in new materials and our own blades, the simple fact is that none of the blades we built over the last two years were as good as Feather's. Our goal isn't necessarily to build blades. We just want to deliver the world's best shave, period.

For now, we are supplying OneBlade razor users with these high-quality Feather blades. You can't currently buy these razors in the U.S. They make them in Japan and we're importing them to our facilities, then distributing them to our users. Another important fact: these are high-carbon steel blades. They are super-sharp and super-smooth. With only a single edge, it's important that you use a new razor for each shave, just like you would see in a barbershop if you were getting a straight razor shave. The blades will cost customers less than $1 each including delivery, so there's no reason to shave with less than a perfect blade. (Or you could just stick with your cartridge razors if you wanted a lousy shave.)

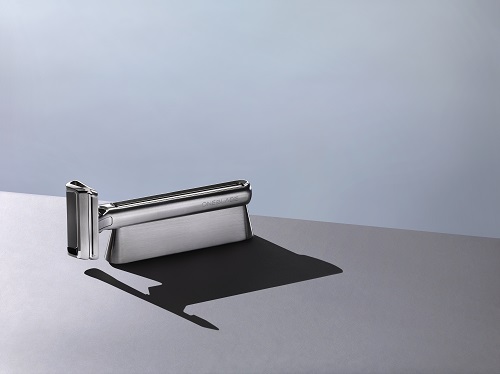

![]() Now... with a great blade in hand, our next challenge was to build a handle that every man would be proud to own... that would look beautiful on his sink... and that would deliver an ultra-close shave without cutting him.

Now... with a great blade in hand, our next challenge was to build a handle that every man would be proud to own... that would look beautiful on his sink... and that would deliver an ultra-close shave without cutting him.

It's no surprise to anyone who has tried double-sided, single blade "safety" razors – the old-fashioned kind your father or grandfather probably used – offer a high-quality shave with almost no skin irritation.

The trouble is, the old-fashioned handles don't offer much in the way of actual safety. If you're not adept at using these kind of heavy steel razors, you are going to cut yourself – sometimes, badly. With OneBlade, we wanted to combine the comfort and quality of a single-blade shave with the safety and convenience of a cartridge razor. Here's what we built:

![]() Our razor will give you the quality and comfort of a straight-razor shave with the safety and convenience you're used to from your cartridge razor.

Our razor will give you the quality and comfort of a straight-razor shave with the safety and convenience you're used to from your cartridge razor.

There are two key principles to understand in our design.

First, we've built this razor with the perfect amount of space between the guard and the blade. Our industrial designers spent thousands of hours with prototypes getting this spacing exactly right. OneBlade will give you a close shave while also making it difficult to cut yourself.

The second design principle is even more important. It's something you can't really see in the picture, though.

Our razor has an innovative floating head. There's a tiny joint between the razor head (which holds the blade) and the handle. Inside the handle, there's a tiny Teflon-coated stainless steel spring that regulates this joint and thus allows the head to "float" on your skin. This controls the amount of pressure you can apply against your face when you're shaving. Our razor was designed with precisely the amount of pressure needed to cut your beard and not your face.

Never too much, never too little... Just like the world's best barbers.

![]() I've been shaving with a OneBlade razor for several weeks and I'm convinced we've built an incredible tool that's far, far superior to anything else on the market. It works. But I wanted our razor to do more than just work. I wanted to give men a world-class tool. The fact is, most men have very few "trophies." Most men don't own jewelry. Most men will never own a handmade car... or collect the best wines. Most men don't walk down halls adorned with rare art.

I've been shaving with a OneBlade razor for several weeks and I'm convinced we've built an incredible tool that's far, far superior to anything else on the market. It works. But I wanted our razor to do more than just work. I wanted to give men a world-class tool. The fact is, most men have very few "trophies." Most men don't own jewelry. Most men will never own a handmade car... or collect the best wines. Most men don't walk down halls adorned with rare art.

Instead, most men collect tools. They don't need to be expensive or rare. They just need to work. We need to know how to use them. And these tools need to last forever. Whether it's your grill tools, your woodshop tools, or your golf clubs... whatever your passion, if you're a man who cares about performance, then somewhere in your life, you have the best tools you can afford.

That's how I believe you should feel about your razor.

Yes, a razor is a tool. But it's a tool that you will use again and again throughout your life. Even if you have a beard, you will probably shave at least a portion of your neck or face. Why not have the highest-quality tools available to you? Why not have the very best? Why not understand how it works and know how to use it?

Having the best tool doesn't need to cost a lot of money... not when it comes to shaving, at least. I believe you'll find that by using our tool – one of the finest that has ever been designed, built, and offered to the public – your total cost of shaving will be significantly less than using the branded cartridge products. So whether you're a millionaire or a laborer... if shaving is a part of your life, you can afford to own the absolute best in the world.

![]() That's why every OneBlade razor is individually numbered. You'll find the individual razor number on the bottom of the head of the razor. And every OneBlade razor is guaranteed for life. If your razor ever breaks for any reason, send it back to us and we'll replace it.

That's why every OneBlade razor is individually numbered. You'll find the individual razor number on the bottom of the head of the razor. And every OneBlade razor is guaranteed for life. If your razor ever breaks for any reason, send it back to us and we'll replace it.

![]() We can make this guarantee because not only is there no plastic in our razor, but our OneBlade handles are made using the highest-quality steel. Lasers firing at more than 5,000 degrees centigrade melt our steel into molten blocks. This steel is then molded into the form of our handle. When you see and feel these handles, you will know this razor isn't a child's toy. It feels like a solid piece of steel. It looks like a piece of art.

We can make this guarantee because not only is there no plastic in our razor, but our OneBlade handles are made using the highest-quality steel. Lasers firing at more than 5,000 degrees centigrade melt our steel into molten blocks. This steel is then molded into the form of our handle. When you see and feel these handles, you will know this razor isn't a child's toy. It feels like a solid piece of steel. It looks like a piece of art.

![]() There are currently two ways to join the OneBlade revolution in shaving.

There are currently two ways to join the OneBlade revolution in shaving.

The easiest way to get started is to simply purchase your OneBlade at www.onebladeshave.com.

Your razor will ship to you beginning on July 6. As I mentioned, the special blades we're using from Feather aren't currently available in U.S. retail locations. So each initial OneBlade buyer will also receive 60 razors from us. Thereafter, every registered OneBlade user will receive30 blades at the beginning of every month, so you'll never have to worry about running out of blades. You can "skip" a month at any point if you find that you're not shaving every day. Or if you'd rather not receive blades automatically, you may purchase them from us in 90-blade packages whenever you need more.

![]() Or... if you're a collector of the world's finest things... you may want to spend a bit more and get one of the first 101 OneBlade razors. We previously auctioned off razors No. 1 through No. 10. However, the remaining 91 razors remain available. We're offering these first 101 OneBlade razors to collectors for $1,000 each. These very limited razors come with an entire year of blades.

Or... if you're a collector of the world's finest things... you may want to spend a bit more and get one of the first 101 OneBlade razors. We previously auctioned off razors No. 1 through No. 10. However, the remaining 91 razors remain available. We're offering these first 101 OneBlade razors to collectors for $1,000 each. These very limited razors come with an entire year of blades.

![]() Whether you purchase a collector's edition or simply become the first person in your neighborhood to own a OneBlade, each new user will receive:

Whether you purchase a collector's edition or simply become the first person in your neighborhood to own a OneBlade, each new user will receive:

| • | OneBlade's revolutionary new shaving handle, with a first-of-its-kind floating-head, single-blade design and a lifetime guarantee. |

| • | A solid steel razor stand built from a single piece of solid steel with a no-slip base for keeping your razor on display in your bathroom. This stand holds your razor at a perfect 90-degree angle, allowing it to dry quickly. |

| • | Two months' worth (60) of the world's finest Feather blades, manufactured in Japan by the world's foremost producer of high-quality blades. There isn't a better blade available anywhere in the world. At the end of the month, we'll begin sending you blades automatically so you'll never run out. Skip a month anytime you wish, or cancel the automatic service and order blades as you need them in groups of 90. |

To order, visit our website www.onebladeshave.com or simply click here.

Regards,

Porter Stansberry

July 3, 2015

|